Dangerous Goods Operations, DG Supplies, Packaging, Uncategorized

Navigating the Essentials of Dangerous Goods Packaging for Transport

Navigating the essentials of dangerous goods packaging for transport: when it comes to transporting dangerous goods, safety is paramount. Whether you’re shipping chemicals, batteries, or other dangerous goods, understanding the nuances of dangerous goods packaging is crucial for compliance, safety, and efficiency. Here, we’ll explore the essentials of packaging these materials to ensure they reach their destination without incident.

Why Proper Packaging is Critical! Dangerous goods pose risks to health, safety, property, and the environment if not handled correctly. The right packaging not only protects the contents but also prevents accidents during transport. Here’s how:

Containment: ensures substances do not leak or spill

Protection: shields the goods from damage due to handling, temperature changes, or transport conditions.

Identification: proper labels and markings allow for quick recognition of hazards by all involved parties.

Key Components of Dangerous Goods Packaging

Primary Packaging

This is the first layer of defence, directly containing the dangerous goods. Materials used must be resistant to the substance they hold:

- Chemicals: often require glass, metal or specific plastics.

- Explosives: need robust, shock-resistant containers.

Secondary Packaging

Designed to provide additional protection, this layer might include:

- Absorbent materials for potential leaks.

- Void fill to fill the gaps between primary and outer packaging.

- Sealable bags or boxes to contain any spillage from the primary packaging.

Outer Packaging

This final layer should withstand external forces.

Boxes, drums, jerrycans; designed, tested and approved to the dangerous goods’ nature, ensuring they can handle the rigours of transport.

Regulations and Compliance

Compliance with international and local regulations is non-negotiable:

- The ICAO Technical Instructions and IATA Dangerous Goods Regulations for air transport.

- The IMDG Code for maritime.

- The Australian Dangerous Goods Code for road & rail transport in Australia.

- The Australian Explosives Code for the road transport of explosives in Australia.

Each regulation specifies packaging requirements, testing standards, and documentation. Always:

- Check the latest regulations, codes and standards to stay compliant.

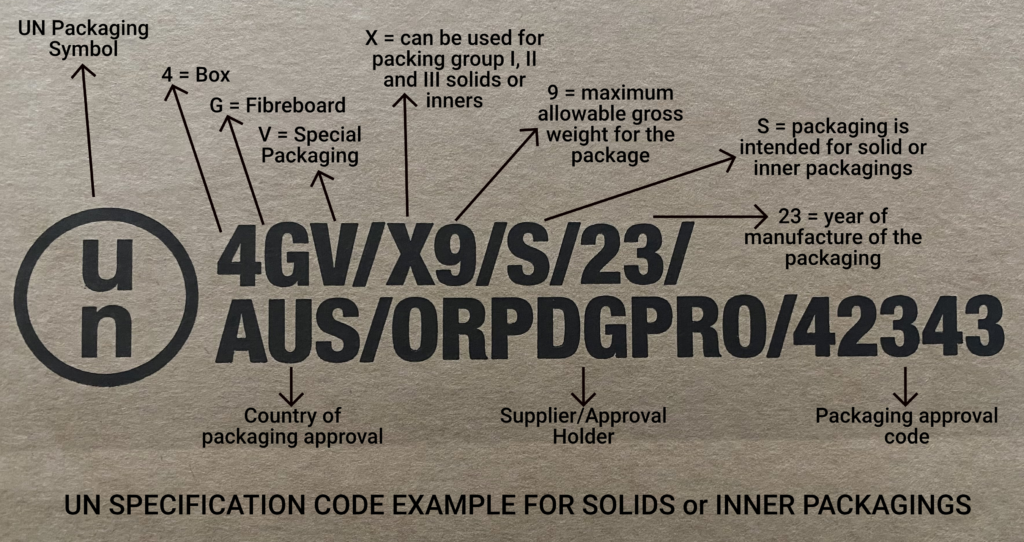

- Use UN approved packaging which has been tested for specific types of dangerous goods (unless non UN approved packaging can be used, as stipulated in the applicable regulations).

Best Practices for Packaging Dangerous Goods

Mark and Label clearly: use hazard labels, proper shipping names, UN numbers, and any other required marks and labels.

Train Staff: ensure everyone involved understands the risks and procedures.

Document Everything: maintain detailed records of packaging and transport conditions.

Conclusion

Transporting dangerous goods safely involves meticulous attention to packaging. By understanding and adhering to the right packaging methods, you safeguard lives, protect the environment, and ensure legal compliance. Remember, the goal is not just to move goods from point A to B, but to do so without incident.

Safe travels to all your dangerous goods shipments!

If you are unsure, or would like to know more about dangerous goods packaging, contact ORP DG PRO.